Wafer Saw

- HOME

- >

- 제품소개

- >

- Wafer Saw

· Wafer Sawing Surfactant

Wafer Sawing 공정에서, Wafer 표면에 Coating 막을 형성하여, Blade로 Sawing 시 발생하는 실리콘 Residue

가 Wafer 표면에 부착되는 것을 억제하고 (Cleaning), 부식 (Corrosion)을 방지하며, Sawing 시 Blade의 열 발

발생을 억제 (Cooling)하여 Blade의 수명을 증가시키는 기능을 제공합니다.

제품 (CL-1203) 주요 특성 및 장점

- Low Surface Tension (30 ~ 32 dyne/cm)

- High Dilution Stability (> 3,000: 1 (DI Water))

- High Suspension Ability for Both Organic & Inorganic Particles

- Anti-corrosion

- Easily Removable and Bio-Degradable

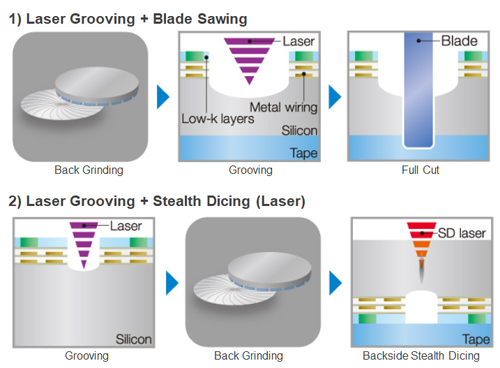

· Laser Grooving Solution

Laser Grooving 방식을 이용한 Wafer Sawing 공정에서, Laser로 Ablation시 발생하는 Debris (Particle)가 Wafer의

표면에 부착되는 것을 방지하고, Wafer 를 Cutting시 Laser 접촉면의 온도를 낮추어 Wafer의 Damage를 방지하기

위한 코팅막을 형성하는 기능을 제공합니다.

제품 (CS-2000) 주요 특성 및 장점

- Excellent Coating Covering and Film Forming Ability

- High Transparency

- Good Adhesion with Organic and Inorganic Substrate

- Lower Surface Tension

- High Purity and Fine Filtration

- Near Neutral Solution (pH:4.0 ~ 5.0)

- Water-Soluble Solution

- Non-Toxic Materials and Solvent

- Good Defoaming Ability

- Easy to Remove after Grooving

- Excellent Heating Stability

- Biodegradable